How To Get Better Speaker Performance Through Decoupling

A premium sound system can cost tens of thousands of dollars, but is also able to prove its value to a listener the second a favorite song reaches its crescendo, or when a blockbuster movie’s big fight scene breaks out. But no matter how much is spent on speakers and receivers, their performance will still be impacted by the room where they reside. This is the reason acoustical treatment is so important for getting the crispest and most impactful sound out of your system. This can be done in many ways, from a wall-mounted sound diffusor, to a series of bass traps placed in the corners of rooms.

One of the greatest issues people encounter while using their stereos and home theaters is the vibration caused by speakers and subwoofers. In addition to the distraction of buzzing and vibrating floorboards, shelving, and loose items, is that these vibrations and low-frequencies can travel through a building’s structure, reaching other rooms or adjoining residences. The best way to cut down on these bothersome vibrations is through decoupling, and The Foam Factory manufactures and sells materials that excel in this application, as well as end-products you use directly off the shelf.

Open-cell foam is useful as a decoupling material, as its miniscule cells create a difficult path for the vibrations of a subwoofer to travel through. The material itself is solid, but by consisting of millions of small, fractured bubbles, the waves are met with alternating areas of open space and foam material which is more difficult to travel directly through. By effectively reducing the sound waves that cause vibration before they reach materials that transmit more easily, room vibration is stopped before it starts.

To accomplish this in your home, The Foam Factory offers monitor isolation wedges that decouple subwoofers and speakers, and also feature angles that help target the generated sound to an ideal listening area. Made of firm charcoal foam, two of these wedges can hold as much as 100 pounds when used side-by-side. While supporting the speaker, the foam’s cellular structure is able to reduce vibrations being transmitted from the sound source and give you clearer sound by reducing vibration and timing issues. When implemented with a bass trap system, acoustic panels, and diffusion, these monitor isolation wedges can help create an ideal space for your music listening and movie watching that delivers crisp, clear sound.

If a store-bought solution isn’t your style, decouplers are one of the easiest DIY acoustical treatments to make at home. A DIY decoupler shares the same principle of the monitor isolation wedge by using open-cell foam to dampen vibration as a sound barrier. The greatest benefit of a DIY decoupler is that you can get the performance benefits of the charcoal foam while tailoring its size and appearance to your room’s setup.

The simplest DIY decoupler consists of firm acoustic absorption foam that provides vibration dampening, placed beneath a piece of MDF (medium-density fiberboard) for a stable support block to hold the subwoofer. MDF is a non-resonant material, important in such setups, since resonant materials are prone to the kind of vibration you’re actively looking to eliminate. An ideal DIY decoupler uses an amount of foam only necessary for safely supporting the speaker and no more, since one way you maximize performance is reducing the stand’s contact with the ground. But by not utilizing enough foam, you run the risk of the heavy subwoofer over-compressing the foam, reducing performance while also creating stability issues. The Foam Factory offers firm charcoal foam in a thickness range from 1 to 3 inches in ½ inch increments, and in sheet sizes 72 inches wide by 80, 40, or 24 inches long. It features a compression value of 70 ILD. Contacting The Foam Factory with your decoupling project plans and the size and weight of your speaker or subwoofer will help them calculate how much studio foam you will need to ensure stability and optimize performance.

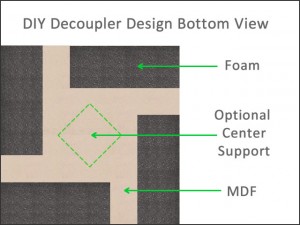

After you’ve determined how much foam your build requires, properly constructing it is the next step. One of the smartest design patterns for the foam is trimming rectangular blocks about 2/3 as long as the edge of the MDF base and gluing them vertically along the edge of the base. Each piece should be perpendicular to the two adjoining pieces and parallel to the piece across the board. It will look like foam is completely lining the edge of the board, with a small gap between each piece so no foam touches. (Refer to the diagram above.) With very heavy speakers, adding a section to the center of the base can help support weight. This will give outer-edge stability while reducing the build’s footprint. The bass foam can be adhered to the MDF board and you will have your own homemade decoupler, designed and painted how you want, for only the price of materials.

Whether you prefer a hands-on approach to handling vibration issues or prefer a ready-made solution to your sound-improvement needs, The Foam Factory has the raw materials and finished products to help your system be heard loud and clear.

Tags: Acoustical Foam, Bass Trap, DIY, Sound Absorption, Studio Foam

Posted in Acoustic Foam

Leave a Reply