Custom Instrument Case Inserts: Protecting Your Investments, One Guitar at a Time

Whether you play in the basement or the world’s biggest stadiums, the life of a musician can involve a ton of travel. While exciting, it takes a toll on people, between the late nights, early mornings, uneven diets, and constant “go-go-go” nature of it all.

The performers aren’t the only ones who are affected by that grind, however. The gear and instruments performers and engineers bring with them are just as prone to wear and tear as the people who use them.

Things like microphones, instruments, monitors, and other recording gear are all tools of the music and audio trade, but unfortunately, are both expensive and fragile, making them easy to damage and hard to replace or repair. And when your ability to do your job well depends on your equipment functioning well, arriving at a gig or assignment to find your gear didn’t make the trip safely is not an option.

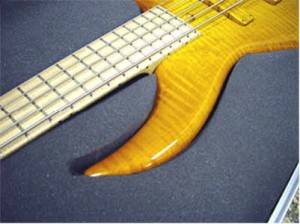

Most gear comes with casing, but these are generally made to protect from outer impact, not full ranges of movement. A basic guitar case is a perfect example. It sits in the case, relatively snugly, but shaking or dropping the case would make it obvious that there is a degree of shock-absorption missing.

Mics are another example. They could be kept in the boxes they came in, but cardboard and rigid foam generally aren’t built to last for a lifetime of in-and-out, back-and-forth usage. Additionally, keeping each in its original packaging means you’ll soon have to juggle and keep track of multiple, easily-lost boxes as you travel.

Luckily, there is a solution to this issue. Whether you have existing cases or are looking to purchase a new one, custom foam inserts are a great addition to your gear packaging for protection, security, and peace of mind.

For individuals who enjoy DIY projects, sheets of sturdy packaging foam can be sliced into snug liners with a serrated blade. Starting from the center of the area being cut out, working outward to the edge, and then around the traced silhouette of the item is the best way to get a smooth edge and gentle contours in curved pieces. An even easier method utilizes Pick and Pull Grid foam. This material features a grid of 1/2″ cubes that can be easily pulled apart by hand, into the shape your equipment. The Foam Factory offers both of these excellent packaging foam varieties in hard-to-soil charcoal foam, as well as static dissipating Anti-Static foam, which is great for electrical equipment and similarly sensitive items. The biggest rule of thumb to follow when making a custom foam casing insert is to always cut your shape a little smaller than the item it will be holding. By doing this, the foam will squeeze against the item when it is inserted, holding it safely in place, reducing movement.

For professional casing, many companies offer custom cutting for their foam padding liners, and The Foam Factory is no exception. Custom cutting offers smooth edges and snug fits, and gives you the ability to easily orient multiple items in a single case, making the most of the space you have, and reducing the number of cases you need to carry. For certain types of equipment, lower-density closed-cell foam may make sense, by offering extra casing protection.

If you’re tired of damaged instruments and gear, sick of lugging around tons of boxes and cases, or just want to protect your investments as best as you can, get ahold of The Foam Factory today, and find out what case insert is right for your application!

Tags: Charcoal Foam, Custom Cut, Foam Insert

Posted in Foam Packaging

I’m looking for a custom cut piece to insert into my guitar case. My guitar is slightly less than 5″ thick. How do I go about finding a custom cut piece so I can fit it into my case?

Please contact us for more information and pricing.

I assume you have made multiple custom cutouts for double neck steel guitars, so what is the ballpark cost of such an item?

Please email us a picture for an estimate on packaging for your guitar. Go to contact us page to reach us. Thanks.

I have a 1965 model Fender Precision Bass. The aftermarket case I have for it doesn’t fit well. How could I add a foam insert to make it better?

We do have pick and pull grid foam that could be used for that purpose. If you want a more precise contour to your musical instrument, then the charcoal regular foam can be cut with a sharp carving knife or electric knife to your needs. Link to our charcoal regular foam is here.

I jave a guitar case that foam degraded looking dor a replacement in the les paul cut out. Is thia something I could purchase from your company.Thank You.

Yes, please contact us for pricing.

Hey- l’m looking to get one of the best foam for my Custom 6 string electric guitar- l got as a b-day gift a very nice and expensive SKB hard case, but they didn’t offer the “Custom cut” for my guitar.

What would be the best foam (hard foam or so) to add in the already existing space for the body, already covered with fabric (a very nice touch and elegant design)- and the best technique to obtain a very nice, and tied result (also covered with the same fabric in the end-… if possible…) . Thank you.

Our pick and pull foam can be used for this application. The foam used is our charcoal regular foam. If you want to go firmer, we do offer charcoal firm foam. The foam can be cut with a sharp carving knife or electric knife.

I have a Mesa Boogie combo amp. The amp is heavy for its size. The original protective foam in the Anvil Case has dry rotted. I need to replace the foam with material that will protect this heavy piece of gear. What do you folks suggest?

Thank you

Dean Newcomb

We would suggest either charcoal FIRM foam or 2.2lb polyethylene foam.

I would like a foam insert 1200mm × 400mm x 75mm for insertion into an existing case and cut out to precisely fit my guitar.

Would this be possible or would I cut the internal shape out myself?What would be the cost ?

Thanks.

Please Contact Usfor details and pricing.

Do you have any coffen case inserts for a bc rich warlock bronze electric guitar

Please Contact Usfor more information on custom cutting for your application!

Looking for 3″ firm guitar case foam

About 45″ x 24″. I am trying to

help a 1955 acoustic guitar case that has

no protection.

Please Contact Usfor information on custom cutting.

We have a keyboard case and the foam is disintegrating. I need to replace it.

The outside dimensions of the case are: 54″ X 17″ X 7 1/2″.

The inside dimensions are: 53″ X 16″ X 4 1/2″ (on bottom) and 2 1/2″ (on top) and the foam is 1″ thick.

I believe I’d need:

two 53″ X 16″ pieces for top and bottom of case

and…

two 53″ X 4 1/2″ pieces for bottom sides (long)

two 16″ X 4 1/2″ pieces for bottom sides (short)

Also…

two 53″ X 2 1/2″ pieces for top sides (long)

two 16″ X 2 1/2″ pieces for top sides (short)

Thank you,

Can you please help me with pricing on enough to replace all in the case?

Please Contact Usfor pricing for your project.

Inquiring about custom guitar foam case inserts

Please Contact Usfor more information regarding your inquiry.

Have you ever done an insert for a Parker Fly (mine is a 1999) and if so, do you still have the specs to use? Thanks –

Thank you for reaching out to TheFoamFactory.com!

Based on your blog question, we do not keep measurements or specs on file. As this information must be provided by each customer, along with the foam type and thickness needed.

Once this information is provided, a representative can then create an emailed estimate for you.

If you have any questions, you can contact us