Product General and Technical Information

Date: 12/12/2021

Name: Expanded Polypropylene

General Information

Expanded Polypropylene Foam (EPP) is a rigid closed-cell foam with great compression and impact resistance. Common applications include heavy duty packaging, signage, roofing strips, and more.

Expanded Polypropylene Foam (EPP) is a rigid closed-cell foam with great compression and impact resistance. Common applications include heavy duty packaging, signage, roofing strips, and more.

| Property | Test Method | Black - 1.3LB | White - 1.5LB |

| Density (LB/Cubic Ft.) | ASTM D3575 | 1.3 | Range, 1.5 - 2.8 |

| Compressive Strength (PSI) @ 10% @ 25% @ 50% @ 75% |

ASTM D3575 | 11.7 14.5 23.5 45 |

14.85 - 32 19 - 42 28.5 - 54 54.5 - 111 |

| Tensile Strength (PSI) | ASTM D3575 | 38 | 46.75 - 67 |

| Tensile Elongation (%) | ASTM D3575 | 20 | 19 - 16 |

| Tear Strength (LB/In.) | ASTM D3575 | 10 | 11.5 - 16 |

| Compression Set (%) @ 25% @ 50% |

ASTM D3575 | 8 14 |

7.5 - 7 13 - 12 |

| Bouyancy (LB/cubic ft) | ASTM D3575 | 60.5 | 60 - 59 |

| Thermal Conductivity (K) | ASTM C177 | 0.26 | 0.25 - 0.26 |

| Thermal Resistance @ 70F (R) | ASTM C177 | 3.8 | 3.9 - 3.8 |

| Coeff. of Lin. Thermal Expansion (in/in/°F x 10^-5) | ASTM D696 | 6.0 | 5.85 - 5.4 |

| Service Temperature (°F; Max.)) | ASTM D3575 | 212 | 212 |

| Water Absorption (% [vol]/lb/ft^2) | ASTM D3575/C272 | <5.0/<0.02 | <5.0/<0.02 |

| Compressive Creep (1000hr, % [PSI]) | ASTM D3575 | 1.8 [1.5] | 1.5 [1.75] - 1.5 [3.0] |

| Flammability (<4.0 in/min) | FMVSS-302 | PASS | NA |

| Chemical Resistance (1 hr exposure [solvents, acids, and alkalines]) | Various | PASS | NA |

| Fuel Immersion (<5% [Change in Volume]) | Coast Guard; Fuel B per 33 CFR § 183.114 | PASS | NA |

All values reported are typical values. We cannot guarantee the applicability or the accuracy of this information or the suitability of the product for any particular purpose. This product is sold without warranty, expressed or implied. (Unless stated otherwise.) Buyer assumes all responsibility for loss or damage arising from the handling and use of this product, whether done in accordance with directions or not. Statements concerning the possible use of this product are not intended as recommendation to use this product in the infringement of any patent.

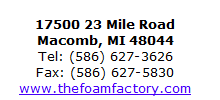

Copyright © 1997-2025 The Foam Factory. All rights reserved.