Understanding the ASTM E84 Fire Retardancy Standard For Foam Sound Treatment Products

No matter how useful or beneficial a product is, if it lacks safety, it shouldn’t be used. Some products can be inherently unsafe, no matter how they are utilized. Fortunately, these rarely make it to stores. Others are completely safe, provided they are used in the right way. Millions of products have many beneficial uses when used properly, while only irresponsible, incorrect or careless use results in a potential hazard.

One material that is incredibly safe when used correctly and even boosts safety in many of its applications is foam. A fantastic product for custom noise reduction, soundproofing foam needs to be utilized properly in the home, as does any material. An individual would never intentionally place foam products next to open flames, just as they would never do the same to curtains or furniture. Accidents happen however, so using foam materials that give an individual a chance to put out a fire is imperative. The importance of manufacturing safe products for all uses is taken seriously at The Foam Factory and is why all acoustic foam they manufacture and sell meets the ASTM E84 flame retardancy standard at its top Class A rating.

Established by the American Society for Testing and Materials, formally known as ASTM International, this evaluation measures a material’s reaction after being exposed to fire, in terms of flame development and smoke production. These testing standards let a customer know if a product has the potential to quickly cause catastrophic damage when exposed to an ignition source, compared to moderately withstanding ignition so that an attempt at extinguishment may be made. The amount of smoke and flame produced by a material is measured against two controls; fiber-reinforced cement board which does not burn or smoke, and red oak flooring, which represents a high flammability level.

The two categories measured in the assessment are Flame Spread Index (FSI) and Smoke Developed Index (SDI) which state, respectively, how far flames generated on the test material spread and how much smoke is generated. The FSI is measured from 0 which indicates no flames, up to 200 which indicates quickly spreading flames. SDI is measured on a scale of 0 to 450, from no smoke generated to thick, heavy smoke. It is important to understand that these measurements are recorded in a controlled environment that cannot fully replicate the events of an unplanned fire in the real-world. However, testing similar materials to the same standard allows for fair performance comparisons to be made.

FSI and SDI values are compiled and applied to a three-tiered class system: Class A, Class B and Class C, also known as Class 1, 2 and 3 in similar coding systems. Class A rated materials produce minimal to no flames or smoke, while Class C produces the most. Class B materials generate a fair amount of both. FSI values must be within 0 to 25 to be classified as Class A, 26 to 75 for Class B and 76 to 200 for Class C. All must also score 450 or lower in SDI. Many building codes use the ASTM E84 standard as a benchmark for construction materials, though it is important to always check local and individual building regulations before beginning any project or installation.

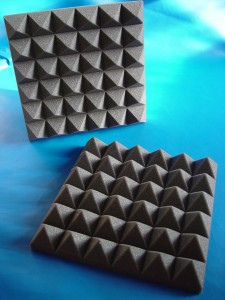

The Foam Factory’s eggcrate, wedge and pyramid foam, corner bass absorbers, broadband absorbers, wall tiles, drop ceiling tiles, rectangular corner blocks, cubed blocks, studio columns and monitor isolation wedges are all Class A rated sound treatment materials. Available in 12 different colors, these acoustical products can be manufactured into other custom projects such as cushions or packaging where fire retardancy is desired. To ensure consistency, fire retardants are added to the foam’s formula during manufacturing, not simply sprayed on the surface.

The Foam Factory’s acoustic foam also performs favorably against competitors. In a 2004 test, Auralex 2 inch Studiofoam, comparable to The Foam Factory’s 2 inch wedge foam, earned a 35 FSI rating and a 350 SDI rating for a cumulative Class B rating. The Foam Factory’s 2010 test of their 2 inch wedge foam registered a 25 FSI and 250 SDI for a Class A rating. Sonex foam, another comparable product made of fire retardant melamine-based foam, scored slightly better FSI and SDI ratings, but melamine-based materials are also less durable and easily soiled. The Foam Factory’s strong and resilient polyurethane foam earned the same overall Class A rating as Sonex.

Despite continuing advances in technology and standards, there is no completely fireproof product and it is important to use products in a way that recognizes this fact. Open flames must always be kept away from acoustical foam or sound insulation, smoking should be avoided and areas with components generating extreme heat should not house acoustical foam installations. Always consult with building professionals and sound experts when planning to install acoustical foam.

Tags: Acoustical Foam, ASTM, Fire Safety, Soundproofing Foam

Posted in Acoustic Foam, Announcements

Can you supply me a technical Data sheet for the 2” 3” and 4” foam.

Link to the technical data for the acoustic foam can be found here.